Incastt Machines

Shell Room

At Incastt Machines, we understand every stage of Investment Casting process is important. The quality & consistency of the secondary slurry decides the strength and permeability of the shell. The ceramic particles,and the binder must be meticulously blended to get a good quality slurry. We understand that each foundry has its own slurry composition, and we have designed our slurry mixer to deliver slurry in a consistent and time bound manner.

The SMSD model operates at a high speed and delivers large quantities of slurry quickly. The SM HS model on the other hand blends the slurry with high shear force. Incastt’s slurry mixer is not only functional but also easy to operate and maintain. Cleaning the vessel has been made hassle free by having the Stainless Steel vessel with an easy dismounting fixture. Whether you use different sizes of ceramic particles or a different type of binder, our slurry mixer will provide with the best results.

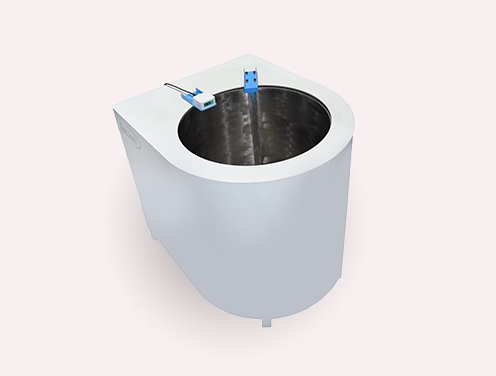

Is your slurry settling down & heavier refractory in the slurry separating? Is your slurry frothing and bubbling? Then you have an ideal solution from us. Our Slurry Pot just addresses this persistent but serious problem in an IC foundry.

The Slurry Pot is designed in such a way that, the slurry is in continuous stirring motion while preventing formation of froth and air bubbles. More than 30 years of experience has taught us, slurry pot is not merely a rotating drum. Incastt’s design team has made sure that servicing and maintaining is quick and easy, as it carries large quantities of expensive slurry which cannot be wasted.

Rainfall Type Stucco Machine

When we talk about shell building, the wet slurry and the dry sand complement each other forming a strong shell. It is important that sand coating is done uniformly. Though this sounds simple, achieving this may be a hard task. At Incastt, this is made as simple with our Rainfall Type Stucco Machine! The self-loading rotary type of elevator produces a sand rain in which the slurry dipped wax cluster is manipulated to obtain a uniform coating of the refractory particles on the cluster.

This process consumes a large amount of sand and its crucial for us to minimise the loss and deterioration of sand quality. You can also have customised features of sand level indicator, speed control to adjust shower density & hopper for the refractory sand which feeds sand automatically into the RTS.

Fluidized Bed Stucco Machine

Backup coating of large sized sand grains is no more a worry for foundries with our Fluidized Bed Stucco Machine. Machine efficiently coats larger grain sizes like like – 16 +30, -30 +40, or -60 +80.

Purpose designed air distribution nozzles are used to ensure uniform fluidizing of the stucco sands. Baffles are provided in the air line and the dust collector line, to enable control the air flow. We have taken care of maximizing worker comfort by designing FBS ergonomically.

A dust collection chute is provided. When connected to an efficient dust collector, this will enable uniform suck out the dust generated during operation.

Shell Dipping Manipulator

Do you have to produce large heavy castings but in small numbers? Are you worried about handling of heavy shells ? This is no more a problem with our Shell Dipping Manipulator designed to help production of large sized castings in small numbers.

The 6-axis manipulator is designed to take the load off the operators / workers hand and yet give him full freedom in handling the shell for dipping and stuccoing.

Investment casting foundries today are facing a challange of producing heavy castings but in very small numbers. Such situation calls for human aided automation solution. Where a person remains in control of the process while the load is borne by the machine.

At Incastt, we understand these nitty-gritties of an Investment Casting foundry. The Shell Dipping Manipulator does just this. The 6-axis manipulator can be used to lift heavy shells and perform complex operations with ease.

The shell manipulator is designed to take the load off the operators / workers hand and yet give him full freedom in handling the shell for dipping and stuccoing.

Manage your dust without allowing it dust the whole shell room! We at Incastt, have developed dust collector to easly manage the dust generated from Stucco Machine / Fluidised Bed Stucco machine.

The Dust Collector through blower and cartridge filter, collecting in funnel below. With the added on feature of reverse pulse, the dust collecting cartridges are automatically cleaned.

At Incastt Machines, we understand every stage of Investment Casting process is important. The quality and consistency of the secondary slurry decides the strength and permeability of the shell. The ceramic particles,and the binder must be meticulously blended to get a good quality slurry. We understand that each foundry has its own slurry composition, and we have designed our slurry mixer to deliver slurry in a consistent and time bound manner.

The SMSD model operates at a high speed and delivers large quantities of slurry quickly. The SM HS model on the other hand blends the slurry with high shear force. Incastt’s slurry mixer is not only functional but also easy to operate and maintain. Cleaning the vessel has been made hassle free by having the Stainless Steel vessel with an easy dismounting fixture. Whether you use different sizes of ceramic particles or a different type of binder, our slurry mixer will provide with the best results.