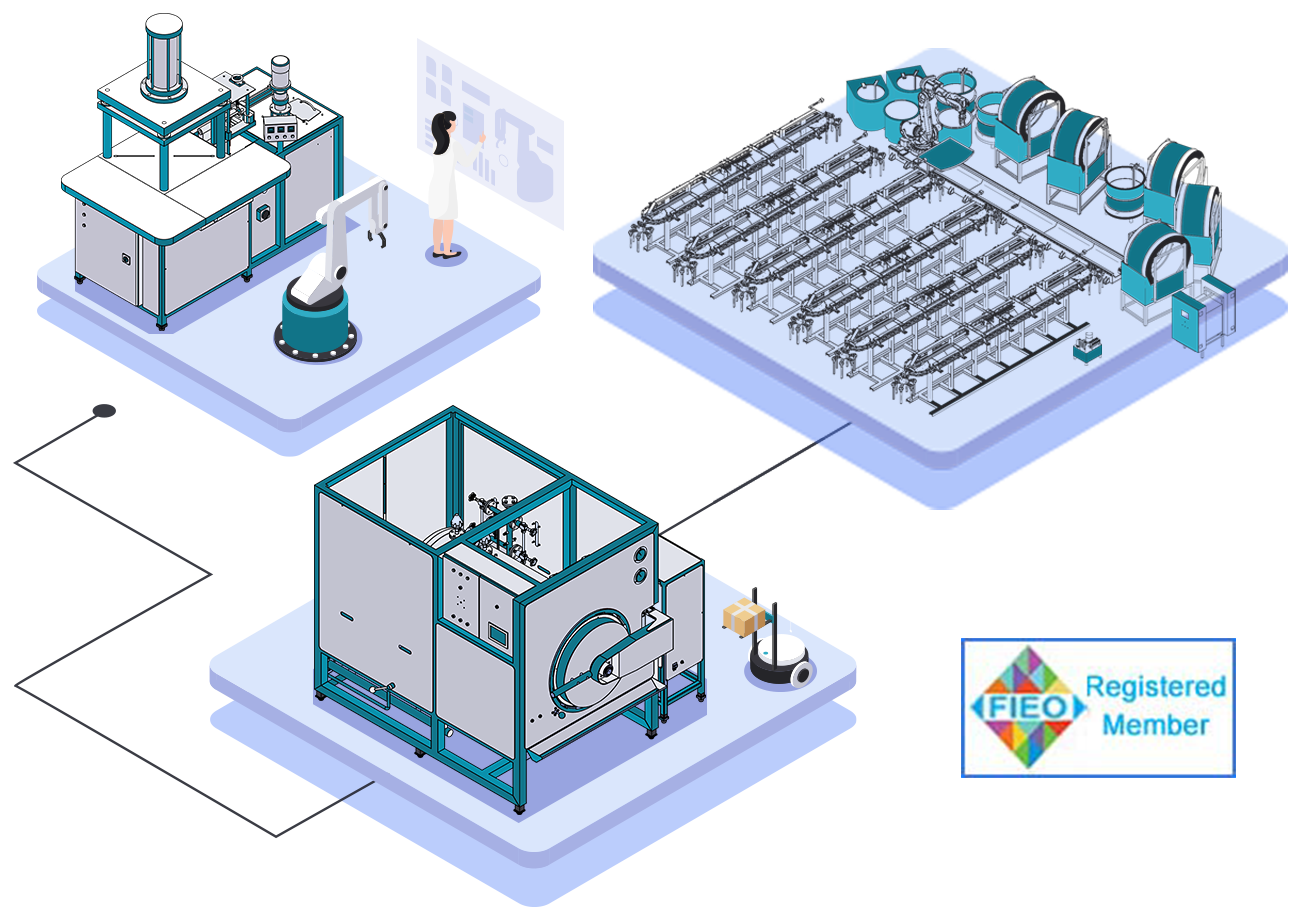

Incastt Machines is a pioneer in offering the Investment Casting Industry with cutting-edge manufacturing technologies. We manufacture World Class machinery, refractories and setting up world class Investment Casting foundry Projects. We have been developing new products for the Investment Casting foundry industry since 2006. Incastt Machines will help you achieve better plant efficiency; reduction in production costs, reduction of rejects and increases in productivity, thereby achieving high returns on your investments. Incastt Machines not only brings you an independent analysis while you choose machines for your plants but also gets you the access to latest methods and technology. We understand investment casting and we understand you. At Incastt Projects, we undertake investment casting foundry projects on a Turn – Key basis. Our services cover complete techno-commercial aspects of investment casting foundries. Under our ‘TURN-KEY PROJECT’ services we cover plant design, technology and machinery required for the investment casting foundry. Incastt Machines

Pioneer in Investment Casting Technology

We design, develop and manufacture the entire range of machinery required for an Investment casting industry.

Incastt Machines – Precision Engineered Investment Casting

Why Choose Us

Incastt Machines

We manufacture and market products that are indigenously developed by us, through our extensive in-house R&D efforts. We do not deal/market any product, not manufactured by us.

We are specialized in Turn-key Projects

We do projects in three categories

Complete new investment casting foundry project (jobbing foundry)

Adding investment casting facility to existing stell foundry

Product oriented investment casting foundry

Talk to our Experts